Purchase Autodesk Autocad Mechanical Software

January Sale!

Limited time: 5% discount on all products! Ends February 1.

Autodesk AutoCAD Mechanical

| Version | Price & Buy |

|---|---|

| 2026.0.1 | |

| 2025.0.1 | |

| 2024.0.1 | |

| 2023.0.1 | |

| 2022 | |

| 2021 64bit | |

| 2020 64bit | |

| 2019 64bit | |

| 2018 x32+x64 | |

| 2017 x32+x64 | |

| 2016 x32+x64 | |

| 2015 x32+x64 | |

| 2014 x32+x64 | |

| 2013 x32+x64 | |

| 2012 x32+x64 | |

| 2011 x32+x64 | |

| 2010 x32+x64 | |

| 2009 |

Buy AutoCAD Mechanical at cheap prices from $45 to $75. Full version with permanent activation — professional mechanical design software for engineers, drafters, and technical documentation workflows without recurring subscription fees.

AutoCAD Mechanical 2026: Specialized Tools for Mechanical Design and Drafting

AutoCAD Mechanical 2026 delivers specialized capabilities designed specifically for mechanical engineers and drafters. The toolset includes access to over 700,000 standard parts, automated documentation features, and built-in engineering calculations supporting ISO, ANSI, DIN, JIS, BSI, CSN, and GB standards.

This 2026 release introduces updated content library parts, revised ISO symbol standards, and enhanced text search functionality. Studies show productivity improvements of up to 55% compared to manual drafting methods in base AutoCAD.

What Is AutoCAD Mechanical 2026

The Mechanical toolset extends AutoCAD with industry-specific features for mechanical design. It provides automation for common drafting tasks and includes intelligent objects that understand mechanical conventions and update dynamically.

AutoCAD Mechanical 2026 functions as a specialized layer within the AutoCAD environment, adding mechanical engineering capabilities without replacing the core drafting platform.

Mechanical Toolset Overview

The toolset integrates directly into the AutoCAD interface through dedicated ribbons and menus. Objects created with mechanical tools carry additional intelligence beyond standard AutoCAD geometry.

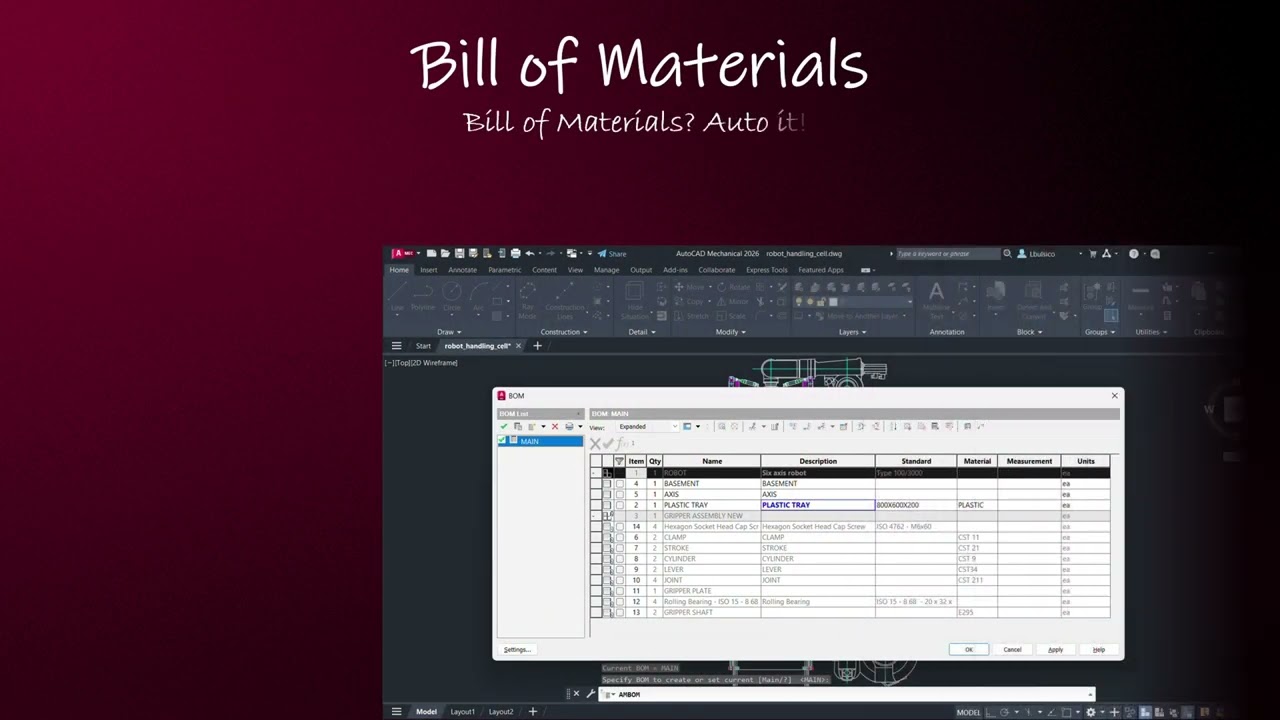

- Automatic BOM Updates: Parts inserted from libraries update bills of materials without manual entry.

- Standards-Compliant Dimensioning: Dimensions apply according to configured standards automatically.

- Intelligent Layer Management: Objects place themselves on appropriate layers based on type and standard requirements.

Who Benefits from the Mechanical Toolset

Mechanical engineers working on component design benefit from the extensive parts library and calculation tools. Drafters appreciate the automated documentation features that speed up drawing production.

Independent designers and small firms gain access to professional-grade tools as a budget-friendly option for home, learning and hobby projects. Students can practice with industry-standard tools while makers design custom parts with accurate specifications.

Industry Standards Support

The software supports seven major international standards systems including ISO, ANSI, DIN, JIS, BSI, CSN, and GB. Each standard controls dimension appearance, symbol display, and part specification conformance.

Dynamic standard switching: Standard parts update automatically when you change the active standard—a metric ISO bolt can switch to ANSI inch specifications with a configuration change.

What's New in AutoCAD Mechanical 2026

The 2026 release focuses on content updates and workflow refinements. More than 675 standard parts received revisions to match current specifications while symbol libraries now reflect the latest ISO standards.

- Enhanced Content Library: Updated ANSI and JIS thread specifications covering external threads, hex nuts, and hexagon head bolts conforming to 2020-2022 revisions.

- ISO 1101:2017(E) Compliance: Feature control frames, datum identifiers, and datum targets used in geometric tolerancing.

- FIND Command Integration: AMNOTE now supports search and replace operations on leader note text through ribbon interface and command line.

- Connected Support Files: Shared configuration across project teams when using Autodesk Docs for drawing storage.

Enhanced Content Library Parts

The content library received 675+ part updates targeting frequently used fasteners and hardware components. ANSI B1.13M metric threads now use the 2005(R2020) revision while ANSI B 18.2.2 hex nuts conform to 2022 specifications.

JIS standards saw significant updates across hexagon head bolts, hex nuts, and helical spring lock washers moving to 2014-2018 standard revisions.

ISO Standard Symbol Revisions

Symbol libraries now support ISO 1101:2017(E) for geometric tolerancing across three symbol types. Feature control frames specify tolerances, datum identifiers establish reference points, and datum targets define specific measurement locations.

The updated symbols display according to current ISO conventions while older drawings remain compatible.

Find and Replace in AMNOTE

The FIND command now searches text within AMNOTE leader notes with a Find & Replace option directly in the Leader Note contextual ribbon tab. The AMNOTEFIND system variable controls search behavior with three settings.

| Setting | Value | Search Scope |

|---|---|---|

| Exclude AMNOTE | 0 | Standard text only |

| User-Defined Text | 1 | Manual note entries |

| Full Search | 2 | User-defined and formula-derived content |

Standard Parts Library and Content Management

The parts library eliminates the need to draw common components from scratch. Bolts, nuts, washers, bearings, and structural shapes insert with a few clicks while generating size variations and view representations automatically.

| Standard | Coverage | Part Categories |

|---|---|---|

| ISO | International | Fasteners, bearings, structural shapes, gears, springs |

| ANSI | US/Imperial | Hardware, threads, steel sections, pipe fittings |

| DIN | German/European | Machine elements, fastening systems, standard components |

| JIS | Japanese | Industrial fasteners, mechanical parts, steel products |

| BSI/CSN/GB | British/Czech/Chinese | Regional standard components and specifications |

Access to 700,000+ Standard Parts

The library contains over 700,000 variations of mechanical components including different sizes, materials, and configurations for each base part type. Parts place as intelligent objects that update the bill of materials automatically.

The AMPOWERVIEW command generates additional views of placed parts including front, side, and section views based on the original insertion.

Creating Custom Content Libraries

Custom libraries store parts specific to your work or industry including company-standard components, specialized hardware, or modified versions of existing parts. The AMCONTENTMANAGER command launches the interface for building these collections.

- Block-Style Content: Simple geometry insertion without BOM integration, suitable for symbols or reference items.

- Full Mechanical Parts: Include size tables, multiple views, and automatic BOM updates like standard library components.

- Network Storage: Libraries store as folder structures with .gdb files for team sharing and consistency across projects.

Content Manager Features

The Content Manager provides tools for organizing and maintaining part libraries. You can add new parts, modify existing entries, and configure insertion behavior with custom properties and metadata.

Define which views generate automatically, specify default layers, and set size parameters to ensure custom content behaves predictably.

Automated Drafting and Documentation Tools

Documentation automation reduces time spent on repetitive tasks. The toolset generates bills of materials by scanning drawings for mechanical parts while dimensions apply according to configured standards automatically.

- BOM Generation: Scans drawings and compiles part lists with quantities, maintaining accuracy as designs change.

- Part Reference Balloons: Attach to components and link to BOM entries, updating automatically when part numbers change.

- Power Dimensioning: Applies standard-compliant dimensions using abbreviated dialogs that remember preferences.

- Automatic Layer Assignment: Places dimensions, annotations, and parts on correct layers without manual switching.

Bills of Materials Generation

BOM commands scan your drawing and extract part information automatically including part numbers, descriptions, quantities, and material specifications without manual data entry. Associative balloons link drawing geometry to BOM entries.

Automatic synchronization: When you move or modify a balloon, it maintains its connection to the corresponding table row, preventing discrepancies between drawings and documentation.

Power Dimensioning and GD&T Annotations

Power dimensioning streamlines the dimension creation process with abbreviated dialog boxes appearing only when necessary. Most settings are controlled by your active drafting standard to minimize repeated input.

GD&T symbol libraries include geometric tolerancing symbols, welding symbols, and surface texture indicators with preconfigured frequently used symbols saved for quick access.

Layer Management Automation

The toolset creates mechanical layers automatically as you work—centerlines go on centerline layers, dimensions land on dimension layers, and parts place themselves according to component type. Layer properties follow your configured standard specifications for names, colors, and linetypes.

Mechanical Drawing Detailing Features

Detailing tools handle tasks specific to mechanical drafting conventions. Centerlines mark cylindrical features and axes of symmetry while hidden line management shows obscured edges correctly.

Mechanical detailing commands understand drafting conventions and apply them consistently, eliminating guesswork about proper symbol placement or line representation.

Centerlines and Hole Charts

Centerline commands generate axis indicators for circular features and symmetric objects with automatic calculation of centerline positions based on geometry. Centerlines update when you modify the associated geometry.

Hole charts catalog all holes in a drawing and present them in tabular format including diameters, positions, and special callouts like thread specifications or counterbore details.

Hidden Lines with AMSHIDE

AMSHIDE manages hidden line representation when objects overlap by defining hide situations between foreground and background objects. The command converts obscured geometry to hidden line display while intelligently ignoring centerlines and hatches.

- Foreground Definition: Any closed contour functions as a foreground element that obscures objects behind it.

- Advanced Functionality: Provides more capabilities than AM2DHIDE for both mechanical structure drawings and general workflows.

Leader Notes and Smart Annotations

AMNOTE creates leader notes that connect to object properties through formulas that extract data from annotated objects. Notes display current object information and update automatically when properties change.

Template-based notes provide predefined formats for common annotations, populating with relevant object data to deliver context-sensitive information without manual text entry.

Engineering Calculations and Analysis

Built-in calculators perform common mechanical engineering analyses without external software. Shaft calculations determine deflection and safety factors, moment of inertia analysis evaluates cross-section properties, and FEA capabilities assess stress distribution.

Calculation results integrate directly into drawings as annotation blocks adjacent to analyzed geometry.

Shaft Calculator

The shaft calculator analyzes rotating and stationary shafts under various loading conditions calculating deflection lines, bending moments, torsion moments, and safety factors. The tool handles solid and hollow shaft configurations with multiple support and loading scenarios.

- Load Types: Supports point loads, line loads, gear forces, and moments with dynamic load min/max values.

- Material Properties: Uses DIN or ANSI standards databases with custom material specification options.

- Safety Analysis: Results show critical stress points and identify where shaft strength may be insufficient following DIN 743 or ANSI methodologies.

Moment of Inertia Analysis

AMINERTIA calculates moment of inertia for cross-sectional profiles. You select a closed contour representing the cross-section, and the command fills the area to confirm selection accuracy before determining principal axes.

- Center of Gravity: Calculates coordinates and moments of inertia along principal axes.

- Load Direction Analysis: Determines deflection angle, maximum extension distance, and minimum compression distance from neutral line.

- Documentation Block: Complete calculation table inserts anywhere in your drawing for manufacturing and verification purposes.

FEA and Load Calculations

Finite element analysis features evaluate stress distribution in mechanical components to identify potential failure points. These calculations run within the AutoCAD environment without launching separate analysis applications.

The tools support various load types and boundary conditions relevant to mechanical design, eliminating the need for third-party add-ins for basic structural analysis.

For Home Users, Learners, and Hobby Projects

AutoCAD Mechanical 2026 serves as a budget-friendly option for home, learning and hobby projects beyond professional engineering environments. Students practicing mechanical drafting gain exposure to industry-standard workflows while home users designing custom parts benefit from standards-based libraries.

The toolset helps learners understand mechanical drafting principles through hands-on practice with standard parts demonstrating how components conform to specifications.

Learning Mechanical Design Fundamentals

Students learning CAD and mechanical design work with the same tools used in professional settings. The standard parts library teaches component selection and proper specification methods while GD&T symbols introduce geometric tolerancing concepts.

Automated features demonstrate correct drafting practices while accelerating learning—instead of puzzling over layer organization, learners see proper implementation as the software applies standards automatically.

DIY and Maker Applications

Makers designing parts for 3D printing, CNC machining, or fabrication use the toolset to create accurate specifications. Standard parts provide reference dimensions for interfaces with commercial hardware.

- Shaft Analysis: Confirms that custom axles can handle expected loads in mechanical assemblies.

- Moment of Inertia: Validates that brackets have sufficient strength for intended applications.

- Engineering Rigor: Brings professional calculation capabilities to hobby projects and personal designs.

Building Custom Parts for Personal Projects

Home users create custom content libraries for ongoing projects—restoration enthusiasts build libraries of vintage hardware while robotics hobbyists catalog motor mounts and structural elements. The Content Manager lets you define custom parts with size variations and multiple views.

These custom parts behave like standard library components with automatic BOM updates and view generation, building into a valuable resource for future projects.

Productivity and Workflow Improvements

Independent productivity studies measured time savings up to 55% faster when using the Mechanical toolset compared to base AutoCAD. These gains come from automation that eliminates repetitive manual operations.

| Task | Manual Approach | Mechanical Toolset |

|---|---|---|

| Standard Part Insertion | Draw geometry from specifications | Select from library, auto-generates views |

| BOM Creation | Count and list parts manually | Automatic scan and table generation |

| Layer Management | Create and switch layers manually | Automatic layer creation and assignment |

| Hidden Lines | Manual line type changes | AMSHIDE automatic obscured edge handling |

Automation vs Manual Drafting

Manual drafting requires drawing every bolt, calculating every dimension placement, and tracking every part for documentation. The Mechanical toolset handles these tasks programmatically with parts from libraries, dimensions following standard rules automatically, and BOMs compiling themselves.

A drawing that might take a full day manually could be completed in half that time with toolset automation.

Reusable Content and Templates

Custom content libraries and configured templates multiply productivity gains across projects. Once you build a library of company-specific parts, every future project benefits from reduced setup time.

Symbol library customization means frequently used annotations insert with a few clicks, creating consistency while reducing redundant work.

Integrated Calculations Without Third-Party Tools

Built-in analysis capabilities eliminate workflow interruptions by performing shaft calculations, moment of inertia analysis, and FEA without exporting geometry to external applications. Results insert directly into drawings as documentation blocks.

Everything from initial concept through final documented design with calculations happens in AutoCAD Mechanical 2026 within a single environment.